|

Loading

|

|

|

Mining Terms

MRS. GASCOIGNE: "We know thee! Tha's done thysen one i' th' eye this time. When dost think tha'll iver get ter be a butty, at this rate? There's Luther nowt b'r a day man yet."

The Daughter-in-Law

In the bad early days before the Truck Acts, the "butty" or "gaffer", a

middleman who contracted with the mining company to deliver an agreed tonnage of

coal to the pithead, hiring and paying his own labour, often conducted his

business as a profitable adjunct to other activities, administering to the

coalfield as merchant, insurer or

brothel-keeper

and, as "butty", finding wages most promptly for his regular customers. There

was widespread opposition to the "butty-system" in the second half of the

nineteenth century, the miners demanding direct employment on piece-work by the

colliery companies, and by 1912 most hewers in charge of "stalls" were

restricted to the employment on a time wage of one man and a boy. As a simple

working arrangement, the system", always virtually exclusive to the Midlands,

continued to operate there, though on a diminishing scale, until the early

1930's. It was peculiar to the "longwall" method of working, the "butty"

contracting to work a particular longwall face and engaging and paying his men,

at a day-rate, out of the contract terms with the company. A small "working

master", he would spend some time hewing the coal himself to set the pace and

expect his men to keep up to it. Any tonnage cut in excess of the minimum agreed

was his profit. He was an envied, but never a popular, figure.

brothel-keeper

and, as "butty", finding wages most promptly for his regular customers. There

was widespread opposition to the "butty-system" in the second half of the

nineteenth century, the miners demanding direct employment on piece-work by the

colliery companies, and by 1912 most hewers in charge of "stalls" were

restricted to the employment on a time wage of one man and a boy. As a simple

working arrangement, the system", always virtually exclusive to the Midlands,

continued to operate there, though on a diminishing scale, until the early

1930's. It was peculiar to the "longwall" method of working, the "butty"

contracting to work a particular longwall face and engaging and paying his men,

at a day-rate, out of the contract terms with the company. A small "working

master", he would spend some time hewing the coal himself to set the pace and

expect his men to keep up to it. Any tonnage cut in excess of the minimum agreed

was his profit. He was an envied, but never a popular, figure.

MRS. PURDY: "A mangy bachelor w' 'is iron-men."

JOE: "But they wunna work."

MRS. PURDY: "They say how he did but coss an' swear about them American cutters. I should like to see one set outer 'im-they'd work hard enough rippin's guts out-even iron's got enough sense for that."

The Daughter-in-Law

Yet even the colliery owner employing men of calibre to

manage his mines, and paying them appropriately, found the prospect of the

new machines, with their questionable reputation, daunting. Prejudice

against the Cutters, said one Mining Inspector in 1902.

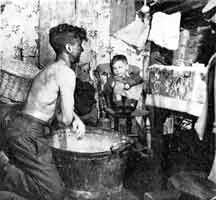

Some dismissed the opposition as the `sorts of vis inertiae that you have to overcome at a great many collieries before you can get any system introduced' and `the usual British conservatism or something of that kind'. But there were often very real technical difficulties. For instance:

Maintenance was a further problem `especially with regard to the electrical apparatus'. There were `not the trained men to look after it.' Blackmore says in `The Widowing of Mrs. Holroyd',

The cutting machines were largely imported from America, where the system was pioneered, but there were British versions. In 1902 the Inventor of the Deep Undercut Coal Cutting Machine reported a gradual increase in his sales since the late 1890's. Yorkshire pits had purchased fifty-three, Lancashire and Derbyshire twenty-two, Nottinghamshire and Staffordshire with five, and Wales with four, showing the least disposition to change. In his opinion, opposition was at least `getting broken down'. He blamed its existence almost equally on genuine operational difficulties (`it was owing to the engineer's fault in not constructing the machines strong enough, causing breakdown, entailing extra work on the part of the men'), on wilful opposition and on the men's instinct for a bargain.

|

Although scarcity of skilled labour and need for economy in the pits led to a considerable increase in the use of coal-cutting machines around 1912 (2,844 machines, operating by means of electricity or compressed air, cut 20,025,964 tons in that year alone), "American Cutters" were not generally tried out in this country until the Second World War. The exception was the Sullivan Ironclad, first introduced about the time of the National Strike. This was a chain cutting machine (others in use at the time worked by disc, bar, percussive and rotary heading) and very successful. The "cutter" was used to undercut the coal in place of hand coaling. This was then blasted down and filled into tubs by hand. "I cannot recall any outcry against this type of machine," a miner of the period recalls. "If there was any loathing of it, I can only think that it was local". The seams of the great Yorkshire and Nottinghamshire coalfield (the Barnsley Bed, the Parkgate or the Deep Hard, the Flockton or the Deep Soft, the Silkstone or the Black Shale) were, generally speaking, well suited to machine-cutting techniques, being thick, comparatively free from "dykes" or faults and only moderately inclined. Possibly the local miners found difficulty in operating the Ironclad at first, or the pits Lawrence recalled presented peculiar difficulties, such as a bad floor or roof, or soft coal working, involving danger from falls and damage to the machines. Luther, too, mentions that "the seams are thin" another disadvantage. In the long run, and with prejudice overcome, the "cutters" represented safer, easier working and better wages for the men. |

MRS. PURDY: "They've gave my mester a diry job o' nights, at a guinea a week, an' he's worked fifty years for th' company, an' isn't but sixty-two now — said he wasn't equeal to stall-workin', whereas he has to slave on th' roads an' comes whoam that tired he can't put's food in's mouth."

The Daughter-in-Law

The

miner's "stall" was his world underground, the limited length of the coalface,

possibly as much as a mile's walk from the shaft, where, perhaps alone, perhaps

with a colleague, he would spend his day, stopping only to wait for the

shot-man, for a meal-break (usually twenty minutes) or for regulation visits

from officials inspecting the roof and walls and testing for gas. Custom counted

for much in the working of a colliery and the location of the "stall" would

depend on the system favoured in a particular locality. "Pillar and Stall" and

"Longwall" were the most widely used in 1912, although "Longwall" was rapidly

displacing the older method. "Pillar and Stall", a survival from the earliest

days of coal-mining, involved cutting the coal into rectangular blocks (or

pillars) by means of "roads" driven out from the shaft towards the boundary and

intersected by others at right angles. These large blocks were then reduced to

smaller sections by a process known as "robbing the pillar" until, in a final

dangerous operation, the last of the coal was removed and the roof allowed to

subside. In "Longwall" the aim was to remove the whole of the seam in a single

continuous operation, "Longwall advancing" working away from the shaft towards

the boundary (so involving "road" maintenance until the coal was completely

cleared), "Longwall retreating" working from the boundary to the shaft (the

"roads" being driven deep into the coal and abandoned as the face was drawn

back). The term "stall" was carried over into "Longwall" where it was peculiar

to hand-cutting and filling, its discussion in the play indicating that this was

a colliery still deeply imbued with tradition. Under both systems, maintenance

of the "roads", clearance of "dirt" and speedy haulage of the coal was essential

to safe and efficient working and, where the miners were on piece-rates, a

living wage for the men. At a guinea a week, Mrs. Purdy's "mester" is unlikely

to have worked a double shift-in any case unusual in 1912 — and, although in one

contemporary opinion, "work on the roadways was far less laborious than hewing

coal at the coalface", his "diry job o' nights" was probably road clearing and

laying, hard, strenuous and unrewarding work over uneven ground. Moreover he

would have suffered a deep hurt to his pride. The colliers or hewers were the

elite of the mining community. Transferred from the coalface to menial, largely

unskilled, work, whether as a labourer or "road-cod" or in the haulage, he would

have felt the humiliation keenly.

The

miner's "stall" was his world underground, the limited length of the coalface,

possibly as much as a mile's walk from the shaft, where, perhaps alone, perhaps

with a colleague, he would spend his day, stopping only to wait for the

shot-man, for a meal-break (usually twenty minutes) or for regulation visits

from officials inspecting the roof and walls and testing for gas. Custom counted

for much in the working of a colliery and the location of the "stall" would

depend on the system favoured in a particular locality. "Pillar and Stall" and

"Longwall" were the most widely used in 1912, although "Longwall" was rapidly

displacing the older method. "Pillar and Stall", a survival from the earliest

days of coal-mining, involved cutting the coal into rectangular blocks (or

pillars) by means of "roads" driven out from the shaft towards the boundary and

intersected by others at right angles. These large blocks were then reduced to

smaller sections by a process known as "robbing the pillar" until, in a final

dangerous operation, the last of the coal was removed and the roof allowed to

subside. In "Longwall" the aim was to remove the whole of the seam in a single

continuous operation, "Longwall advancing" working away from the shaft towards

the boundary (so involving "road" maintenance until the coal was completely

cleared), "Longwall retreating" working from the boundary to the shaft (the

"roads" being driven deep into the coal and abandoned as the face was drawn

back). The term "stall" was carried over into "Longwall" where it was peculiar

to hand-cutting and filling, its discussion in the play indicating that this was

a colliery still deeply imbued with tradition. Under both systems, maintenance

of the "roads", clearance of "dirt" and speedy haulage of the coal was essential

to safe and efficient working and, where the miners were on piece-rates, a

living wage for the men. At a guinea a week, Mrs. Purdy's "mester" is unlikely

to have worked a double shift-in any case unusual in 1912 — and, although in one

contemporary opinion, "work on the roadways was far less laborious than hewing

coal at the coalface", his "diry job o' nights" was probably road clearing and

laying, hard, strenuous and unrewarding work over uneven ground. Moreover he

would have suffered a deep hurt to his pride. The colliers or hewers were the

elite of the mining community. Transferred from the coalface to menial, largely

unskilled, work, whether as a labourer or "road-cod" or in the haulage, he would

have felt the humiliation keenly.

Manager: You never knowed such a thing in your life. Here's a man holin' a stint, just finishin', an' a lot o' stuff falls behind him, clean as a whistle, shuts him up safe as a worm in a nut and niver touches him-niver knowed such a thing in your life.

The Widowing of Mrs. Holroyd

I

believe that accidents are pretty frequent', said a Staffordshire viewer,

describing the system in the nineteenth century.

I

believe that accidents are pretty frequent', said a Staffordshire viewer,

describing the system in the nineteenth century.

`The first process in this working is to dig out five or six feet at the bottom of the seam, but leaving a single strong pillar in the middle of the great mass of coal, which pillar they call the `man-of-war'; it is a square pillar, left in the middle of the side of work, about four or five yards square. It supports the immense mass of about 30 feet thick, like a pillar or pedestal of coal, The workmen then dig upwards all round the mass, making footholes on each side as they proceed upwards, forming a narrow niche, barely sufficient to allow them shoulder-room to get to work in. It frequently happens (I have not been in to experience it myself) I am informed, that one of the leaves of coal will give way and crush the bodies of those men in the niches, and that lives are lost in that manner. After they have proceeded to a certain height, the last operation is to remove the `man-of-war', which is done by passages driven through it horizontally. It then stands on four slender legs, which sometimes yield, and are crushed from the weight above. But if that should not happen, the workmen strike against the legs of this man-of-war, till they nibble and weaken them, so that they give way to the pressure, and down comes the mass together'.

Inevitably many lives were lost. Asked who warned the men of a fall of coal, a miner replied

`Nature itself, which is the best agent that can be employed in that respect. When a piece of coal is about to fall, it makes a low crackling noise, just like the gentle noise of breaking a stick. Little pieces of coal, called the forerunners, are generally heard to fall. The person who first hears the noise (and their ears are very quick) cries out immediately, `Listen', and everything is perfectly still, there is a death-like silence instantly, and if the crushing of the coal continues they withdraw as fast as they are able.'

Grandmother: `Eh, Mr. Chambers, what's this affliction in my old age. You kept your sons out of the pit, but all mine's in. And to think of the trouble I've had-to think o' the trouble that's come out of Brinsley pit to me.'

Manager: `It has that, it 'as that, missis. You seem to have had more'n your-share; I'll admit it, you have.'

The Widowing of Mrs. Holroyd

Joe: That's curious, Bettesworth — I must have a report. Do you know anything about it, or don't you? It happened in your stall; you're responsible for it, and I'm responsible for you.'

The Daughter-in-Law

The office of Colliery Manager today is not a sinecure; in fact, there are

few positions where the duties are more onerous and responsible. To the youthful

aspirant looking up from the bottom rungs of the mining ladder there is an

attractive glamour surrounding the office, which engenders a healthy ambition in

his breast.

To the grey-headed worn-out veteran who becomes reminiscent, there is food for

solemn reflection on perils escaped and victories won. The strikes of labour,

the disasters of the mine from inrushes of water and explosions of fire-damp,

the legal proceedings against recalcitrant workmen who risked their own and

fellow-workers lives, enable him to realise to its fullest that `uneasy lies the

head that wears a crown'.

To the grey-headed worn-out veteran who becomes reminiscent, there is food for

solemn reflection on perils escaped and victories won. The strikes of labour,

the disasters of the mine from inrushes of water and explosions of fire-damp,

the legal proceedings against recalcitrant workmen who risked their own and

fellow-workers lives, enable him to realise to its fullest that `uneasy lies the

head that wears a crown'.

How to Become a Colliery Manager, (Wigan, 1906) Price 2/6d.

Manager: `I should think the inquest'll be at th' New Inn tomorrow, missis. I'll let you know.'

Mrs. Holroyd: `Will there have to be an inquest?'

Manager: `Yes — there'll have to be an inquest.'

The Widowing of Mrs. Holroyd

Inquests

were usually held in the local pub which would be convenient both in point of

location and as the centre of the miners' corporate life — the Miners'

Association `lodges', the Foresters and Oddfellows Societies (always strong in

colliery districts), the monthly meetings of the local Welfare (Provident) or

`Burial' Clubs all traditionally took place there. In addition most pubs had

outbuildings where the bodies of the victims could be housed for viewing by the

Coroner and Jury. One small boy living in a mining area at the time of the

Lawrence plays recalls how he was excited by an unusual commotion at the local

pub and crept round to the rear to see what had been happening. Peering through

the keyhole of the locked door of one outbuilding he saw the body of a miner

laid out on a table, the hands in particular dreadfully apparent. He slunk home,

too terrified even to recount what he had seen and the sight remained with him

vividly fifty years later.

Inquests

were usually held in the local pub which would be convenient both in point of

location and as the centre of the miners' corporate life — the Miners'

Association `lodges', the Foresters and Oddfellows Societies (always strong in

colliery districts), the monthly meetings of the local Welfare (Provident) or

`Burial' Clubs all traditionally took place there. In addition most pubs had

outbuildings where the bodies of the victims could be housed for viewing by the

Coroner and Jury. One small boy living in a mining area at the time of the

Lawrence plays recalls how he was excited by an unusual commotion at the local

pub and crept round to the rear to see what had been happening. Peering through

the keyhole of the locked door of one outbuilding he saw the body of a miner

laid out on a table, the hands in particular dreadfully apparent. He slunk home,

too terrified even to recount what he had seen and the sight remained with him

vividly fifty years later.